Pioneering Strategies for Efficient Energy Management in Manufacturing

Introduction: As the industrial sector continues to evolve, the adoption of efficient energy management practices has emerged as a pressing concern. Businesses are now recognizing the significant impact that energy optimization can have on their operations, competitiveness, and bottom line. This article delves into the realm of energy management in manufacturing, offering a fresh perspective on its importance, benefits, and implementation strategies.

A Historical Overview of Energy Management in Manufacturing

The concept of energy management in manufacturing is not new. In the early 20th century, industry pioneers began to understand the importance of optimizing energy usage in their processes. However, it was not until the energy crises of the 1970s that businesses started to pay serious attention to energy management. With the rise in energy prices, firms realized that energy efficiency could significantly reduce operating costs. Over the years, advancements in technology and growing environmental concerns have further underscored the need for effective energy management in manufacturing.

Current Trends and Insights

Today, energy management is a critical aspect of sustainable business practices. The global emphasis on reducing carbon emissions has led to various regulatory measures pushing companies to adopt more energy-efficient operations. Many businesses are also realizing the economic benefits of energy management, such as lower utility costs and improved competitiveness.

Recent studies have shown that companies with effective energy management programs can achieve up to a 20% reduction in energy costs. These savings can be reinvested into the business, leading to improved operational efficiency and profitability.

Impact of Efficient Energy Management

Implementing efficient energy management practices in manufacturing can bring about numerous benefits. For one, it reduces operational costs by minimizing energy wastage. This can significantly enhance the profitability of a firm.

Moreover, energy-efficient practices contribute to sustainability. By reducing energy consumption, businesses can decrease their carbon footprint, contributing to global environmental conservation efforts.

However, implementing energy management protocols comes with its challenges. It requires a significant upfront investment and a change in organizational culture. Employees at all levels must be trained and motivated to adopt energy-efficient practices.

Practical Energy Management Strategies

To effectively manage energy in manufacturing, businesses can adopt the following strategies:

- Conduct regular energy audits to identify inefficiencies.

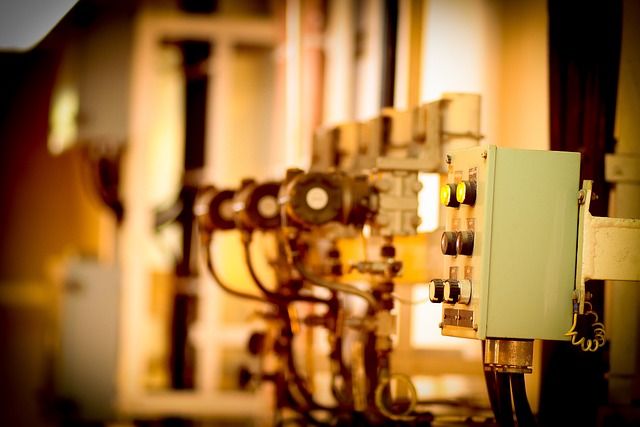

- Invest in energy-efficient machinery and equipment.

- Implement energy management software to monitor and control energy usage.

- Train employees on the importance of energy efficiency and how to implement it in their daily operations.

The Road Ahead for Energy Management in Manufacturing

The future of energy management in manufacturing looks promising. With advancements in technology and increasing awareness about environmental conservation, businesses are expected to continue prioritizing energy efficiency. This shift not only benefits the bottom line but also contributes to a more sustainable future for all.

In conclusion, efficient energy management is crucial for businesses in the manufacturing sector. It offers a host of benefits, from cost savings to environmental conservation. However, to reap these benefits, businesses must invest in the right strategies and foster an organizational culture that values energy efficiency. It is a journey that requires commitment, but the rewards are well worth the effort.