Manufacturing 4.0: Accelerating Industrial Performance through Data Analytics

In the business and industrial landscape, Manufacturing 4.0 is not a new concept. However, its application and significance have evolved over the years, becoming an essential element in today's competitive climate. This article will delve into the world of Manufacturing 4.0, exploring its foundations, current trends, and the potential it holds for future industrial advancement.

A Deeper Dive into Manufacturing 4.0

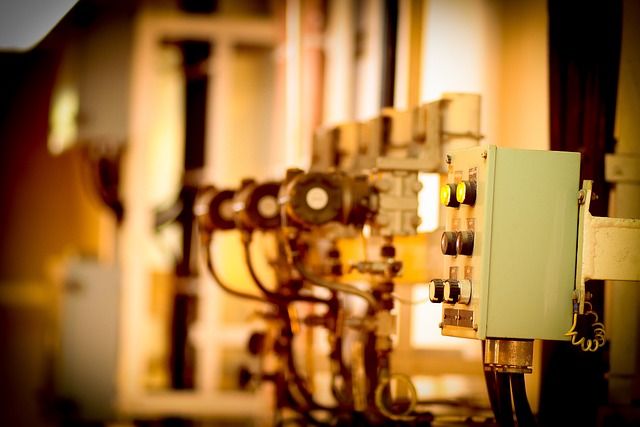

Manufacturing 4.0, often referred to as the fourth industrial revolution, represents a new phase in industrial development that centers around interconnectivity, automation, machine learning, and real-time data. Unlike its predecessors, Manufacturing 4.0 merges the physical and digital worlds through cyber-physical systems, bringing unprecedented changes to the factory floor. This fusion of technologies provides a significant leap from traditional automation to fully connected, flexible systems that can learn and adapt to new conditions.

Manufacturing 4.0 and Data Analytics: A Vital Intersection

One of the most significant trends in Manufacturing 4.0 is the utilization of data analytics. Data analytics enables businesses to make data-driven decisions, optimizing their operations, enhancing productivity, and fostering innovation. By leveraging large volumes of data from various sources, companies can gain actionable insights into their operations, allowing for more accurate forecasting, process optimization, and improved product quality.

Impact, Benefits, and Challenges of Data Analytics in Manufacturing 4.0

The integration of data analytics in Manufacturing 4.0 has a profound impact on industrial operations. It allows for real-time monitoring of processes, predictive maintenance of machinery, and improved efficiency, leading to reduced downtime and cost savings.

However, the adoption of data analytics is not without its challenges. These include data security concerns, the need for skilled data scientists, and the requirement for significant investment in infrastructure and technology. Despite these hurdles, the benefits of integrating data analytics in Manufacturing 4.0 are undeniable, resulting in a competitive edge for businesses that embrace this trend.

Enhancing Industrial Performance with Manufacturing 4.0

-

Embrace interconnectivity: Manufacturing 4.0 thrives on interconnected systems. Ensure your machinery, systems, and processes are interconnected for seamless data flow and analysis.

-

Invest in suitable technology: The right technology is crucial for effective data analytics. This includes data storage, processing systems, and analytics tools.

-

Develop a skilled workforce: The successful application of data analytics requires a workforce that understands its nuances. Invest in training and skill development for your employees.

-

Prioritize data security: With increased data flows comes the need for robust security measures. Ensure your data is protected to maintain trust with your stakeholders and comply with regulatory requirements.

In conclusion, Manufacturing 4.0, with its emphasis on data analytics, is an essential component in the future of industrial operations. While the journey towards complete adaptation may be fraught with challenges, the benefits it brings to the table – enhanced efficiency, reduced costs, and improved product quality – make it a worthy pursuit for businesses seeking to stay ahead in the competitive industrial landscape.