Fostering Growth with Low-Volume, High-Mix Production

In a rapidly changing global business environment, one model gaining traction is the low-volume, high-mix (LVHM) production model. This approach, increasingly adopted by manufacturers worldwide, focuses on producing a wide variety of products in smaller quantities. This article delves into the evolution and implications of this trend, providing a comprehensive understanding of LVHM and its potential impact on business and industrial operations.

The Genesis of Low-Volume, High-Mix Production

LVHM production is not a new concept but has gained importance with the rise of Industry 4.0 technologies. Traditionally, manufacturers focused on high-volume, low-mix (HVLM) production, which emphasizes producing a limited range of products in large quantities. The LVHM model, on the other hand, is characterized by its flexibility, customization, and quick response to market demands.

The advent of digital technologies has been instrumental in promoting LVHM production. Advanced data analytics, agile manufacturing techniques, and sophisticated supply chain management tools have made it possible to switch seamlessly between different product lines, even at a smaller scale.

Embracing the Low-Volume, High-Mix Model: Current Trends

Today, more businesses are recognizing the value of LVHM production. This shift has been driven primarily by changing consumer preferences, which increasingly favor personalized and unique products over standardized ones. Moreover, the rise of e-commerce platforms has facilitated the distribution of a wider variety of goods, further propelling this trend.

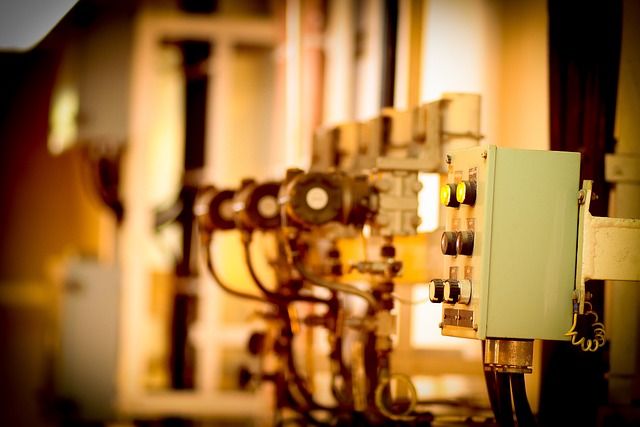

Several industries have seen the successful implementation of the LVHM model. For instance, the electronics industry, with its rapidly changing product lines and short product life cycles, has significantly benefited from this approach. Similarly, the automotive industry has seen the rise of customized vehicles, made possible through LVHM production.

Potential Impact and Challenges of the LVHM Model

While the LVHM model offers numerous benefits, such as improved customer satisfaction and potential market differentiation, it is not without challenges. Firstly, managing a diverse product portfolio can be complex and requires significant planning and coordination. Secondly, achieving economies of scale might be more challenging in a LVHM environment compared to a HVLM model.

Despite these challenges, the LVHM model can be a game-changer for businesses that can successfully navigate its intricacies. Companies need to invest in advanced technology, robust supply chain management, and skilled workforce to effectively implement this model.

Pragmatic Insights: Adapting to the LVHM Model

-

Understand your customer: The LVHM model requires a deep understanding of customer needs and preferences. Regular customer feedback and market research are essential.

-

Invest in technology: Advanced technologies like IoT, machine learning, and data analytics can help manage the complexities of LVHM production.

-

Develop agile supply chains: A flexible, responsive supply chain is crucial in a LVHM environment. Consider strategies like just-in-time inventory management and supplier diversification.

-

Train your workforce: Employees need to be adaptable and skilled in managing diverse product lines. Regular training and development programs can help.

In conclusion, the shift towards LVHM production appears to be more than a passing trend. As consumer preferences evolve and technology advances, companies that can effectively implement this model stand to gain a competitive edge. However, successful adoption requires a thorough understanding of the model’s intricacies, investment in technology, and a focus on workforce development. In an increasingly dynamic and unpredictable business landscape, the LVHM model could well be the key to business growth and success.